Trustworthy Supplier

Application of corn steep liquor to fresh straw silage

Release time:

2024-05-29

Corn steep liquor powder -- high protein feed additive 43% soluble protein, 35% amino acid, 8% moisture, 31% carbohydrate, 21% lactic acid, There are a wide range of applications such as silage feed, ruminant feed, poultry feed, pig feed, etc.

1: why do we need to implement a silage?

Low digestibility and low protein content are two important factors restricting the use of straw as ruminant feed. Silage is a cost-effective way to improve digestibility, nutrient content and palatability of rice straw.

The low digestibility of rice straw was mainly due to the excess of neutral detergent fiber (NDF) and acid detergent fiber (ADF). The higher the NDF content, the lower the animal's feed intake. High neutral detergent fiber content in feed, animal to feed intake is low; When acid detergent fiber content is high, digestibility of forage will decrease. And the protein content of straw is naturally low and needs to be mixed with high protein additives to be used as feed.

Silage can significantly reduce the fiber content, and the nutrients added during silage can not only increase the nutrient content of feed such as protein, but also improve the fermentation quality of silage. For example, The application of molasses and potato pulp to straw silage can significantly increase the concentrations of crude protein, water-soluble carbohydrate and lactic acid, and reduce the contents of neutral detergent fiber and acid detergent fiber.

2: Why choose to add corn steep liquor during the silage process?

Increase nutrients such as crude protein

Corn steep liquor is rich in protein and amino acid. The crude protein content of silage fermented with corn steep liquor added to fresh straw was 14.99%-21.20%, which was significantly higher than that without corn steep liquor added. The neutral detergent fiber and acid detergent fiber contents were significantly reduced. These results showed that the addition of corn steep liquor significantly improved the quality of silage, reduced the difficulty of digestion, and preserved the crude protein well.

Inhibit the growth of bacteria

The results showed that the concentration of lactic acid and acetic acid in silage could be increased by medium concentration of nitrogen source additives. Acetic acid is considered to be a powerful fungal inhibitor and plays an inhibitory role in aerobic spoilage of silage. Therefore, the addition of corn steep liquor as a nitrogen source in the silage process can not only increase the lactic acid concentration, but also increase the acetic acid content and inhibit the breeding of spoilage bacteria in the feed.

Stable PH value

The optimal pH value of silage was 4.0-4.3, and the PH value of corn steep liquor was 4.0-4.5. The use of corn steep liquor keeps the pH in the optimal range and has a buffering effect. The PH of the feed after 60 days of corn steep liquor silage is about 4.0 ~ 4.2, which is enough to ensure the good preservation of the silage. The PH of the silage without corn steep liquor dropped sharply to 3.95 after 3 days of silage.

3: Precautions in the silage process

(1) Attention should be paid to the concentration of corn steep liquor;

The concentration of corn steep should not be too high, otherwise some of the inhibiting components will inhibit the growth and reproduction of microorganisms. It has been proved that high concentration of corn steep can delay the growth of lactic acid bacteria, thus inhibiting the formation of lactic acid during the whole silage period.

(2) Need to pay attention to the inoculation and selection of lactic acid bacteria;

In the process of silage fermentation of fresh straw, lactic acid bacteria are difficult to attach to the straw. Therefore, it is necessary to pay attention to the selection of inoculants to ensure the silage effect.

(3) It is necessary to pay attention to the optimal use time of silage;

According to the experimental conversion, our product consumption: corn steep liquor powder: 92g/kg ~ 115g/kg, 60% Concentrated corn steep liquor: 190g/kg ~ 150g/kg; Silage containing higher crude protein can be obtained, but it should be noted that after being removed from the silo, the best use time in an aerobic environment is about 37 to 63h, and more time may cause problems such as the loss of some feed nutrients.

It is recommended to conduct a small experiment before mass use to achieve the desired effect.

If you are interested in corn steep powder, please email us

https://www.sdjuci.com/product/Products-5

E-mail : sales@jucitrade.com

Blogs

Corn Steep Liquor Powder: The "Nutritional Engine" in Industrial Fermentation

In the fields of bio-pharmaceuticals, amino acid production, and enzyme preparation production within industrial fermentation, the quality of fermentation media raw materials directly impacts the production efficiency and product quality of microbial fermentation. As a practitioner in the industrial fermentation sector, are you searching for a high-quality fermentation raw material that can enhance production efficiency, reduce costs, and improve product quality? Corn Steep Liquor (CSL) powder is your optimal choice.

Corn Steep Liquor Powder: A New Choice for Organic Agricultural Fertilizers

Selecting an efficient and eco-friendly organic fertilizer is crucial for enhancing soil quality and promoting crop growth. Corn Steep Liquor (CSL) powder emerges as a novel option in the realm of organic agricultural fertilizers.

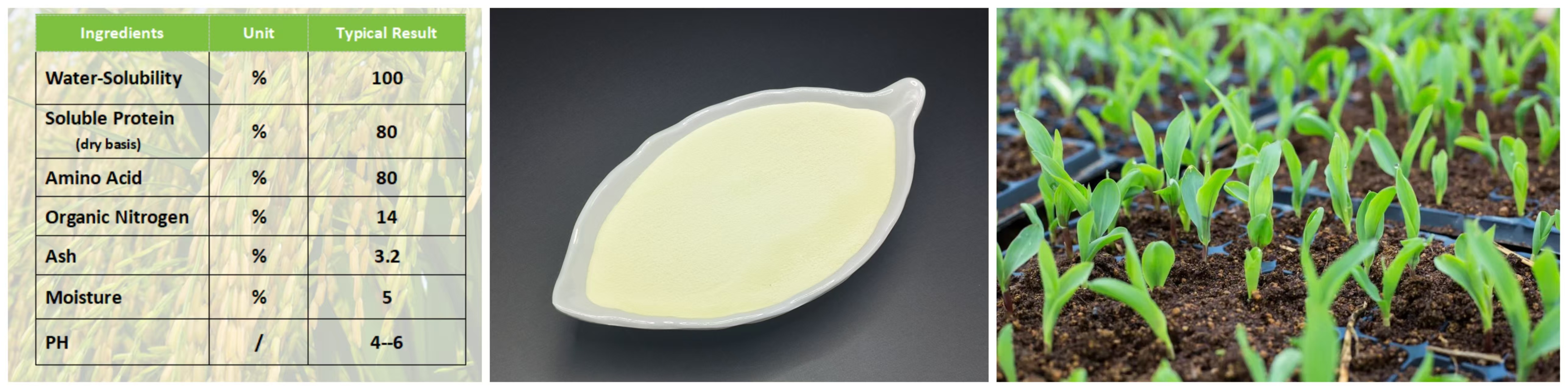

What are the benefits of applying amino acid powder(NPK 14-0-0) to plants?

Amino acid powder can provide organic nitrogen, and plants can directly absorb and utilize the amino acids in the amino acid powder through roots or leaves, making it easier to produce protein and saving the energy required to produce amino acids.

Corn steep liquor powder: Cost-effective Feed Additive

Corn steep liquor powder can be used as a feed protein source or as food for beneficial microorganisms in feed fermentation (fermentation medium), promoting the growth of beneficial microorganisms, thereby improving the nutritional utilization of feed, reducing feed costs, and improving animal growth performance; it is widely used in feed additives for ruminants, chickens, aquatic feed, etc.

Corn Steep Liquor Powder: High-quality fermented feed ingredients

the use of feed produced by adding CSL powder fermentation can reduce and improve feed digestibility, reduce morbidity, increase daily weight gain, improve feed digestibility, and reduce feed-to-meat ratio, which has extremely high economic value.

Corn steep liquor powder: high-quality nutritional supplement for ruminants

corn steep solids and molasses can safely replace the concentrated feed in the diet, providing cows with abundant energy and protein; And it will not affect the feed intake of cattle. CSL powder contain 43% crude protein, 35% amino acids, 7% organic nitrogen, 21% lactic acid, and 31% carbohydrates. It is commonly used in the feed industry as a protein source for cattle, sheep and other animals.