Trustworthy Supplier

The Promoting Effect of Corn Steep Liquor Powder on Glutamic Acid Production

Release time:

2024-07-15

Corn steep powder contains various vitamins, such as vitamin B2 (also known as riboflavin), which can effectively stimulate the accumulation of glutamate; It also contains vitamin B7 (also known as biotin), which significantly affects the permeability of cell membranes. During glutamic acid fermentation, the presence of biotin in the early stage can promote bacterial reproduction; When producing glutamate, a shortage of biotin can affect cell membrane synthesis and promote glutamate production.

1: Selection of Culture Medium for Glutamic Acid

The preparation of culture medium is crucial in the industrial fermentation production of glutamic acid; Usually, fermentation raw materials such as soybean meal, corn steep liquor, and urea can be used as the culture medium for preparing glutamic acid.

Corn steep liquor is a high-quality fermentation raw material with significant effects and Cheap price; Experimental results have shown that among various natural nutrients, corn steep liquor and meat extract have the greatest increase in the accumulation of glutamic acid (3-4 times higher than before), but corn steep liquor is much cheaper than meat extract and has a very high cost-effectiveness.

It contains various vitamins, biotin, and other bio-active molecules that inorganic nitrogen sources such as urea do not possess; Increasing the amount of corn steep liquor in the fermentation medium can replace or reduce the use of fermentation nitrogen sources such as soybean meal and meat extract, which is an economically effective method to reduce production costs.

2: The Promoting Effect of Corn Steep Liquor Powder on Glutamic Acid Production

Corn steep liquor powder is extracted from fresh corn steep liquor and processed into a powder form through a special process to completely retain the nutrients in the corn steep liquor. It is easy to store, not prone to spoilage, and easy to transport and use.

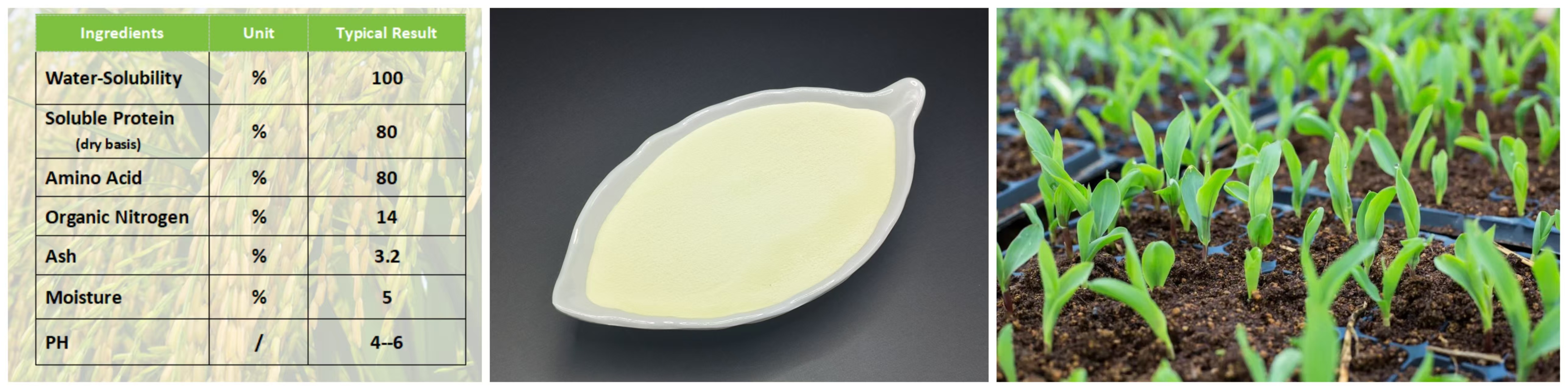

Corn steep powder contains 7% organic nitrogen and can be used as a nitrogen source; It also contains a large amount of amino acids, multiple vitamins, and other bio-active molecules, which can promote bacterial growth, improve fermentation yield, and increase sugar acid conversion rate;

Phosphorus is a component of proteins and nucleic acids, so the amount of phosphorus content can affect the fermentation process of amino acids; Corn steep powder contains 7% phosphorus, which can balance the phosphorus concentration in the culture medium and prevent problems such as slow bacterial growth caused by low phosphorus concentration.

Corn steep powder contains various vitamins, such as vitamin B2 (also known as riboflavin), which can effectively stimulate the accumulation of glutamate; It also contains vitamin B7 (also known as biotin), which significantly affects the permeability of cell membranes. During glutamic acid fermentation, the presence of biotin in the early stage can promote bacterial reproduction; When producing glutamate, a shortage of biotin can affect cell membrane synthesis and promote glutamate production.

3: The Effect of Corn Steep Liquor Concentration on Glutamic Acid Production

When producing glutamic acid, the concentration of corn steep liquor needs to be controlled within an appropriate range, otherwise it will have an inhibitory effect on the production of glutamic acid.

The experiment found that the optimal concentration of corn steep liquor for producing glutamic acid is 100 mg/L. When corn steep liquor is added to the culture medium at a concentration exceeding 2 g/L, glutamate does not accumulate, but cells will grow and reproduce in large numbers.

Therefore, it is recommended to conduct small-scale experiments before using corn steep powder on a large scale to determine the most suitable concentration for you to achieve the desired effect.

If you are interested in corn steep powder, please email us

https://www.sdjuci.com/product/Products-5

- mail : sales@jucitrade.com

Back before

Blogs

Corn Steep Liquor Powder: The "Nutritional Engine" in Industrial Fermentation

In the fields of bio-pharmaceuticals, amino acid production, and enzyme preparation production within industrial fermentation, the quality of fermentation media raw materials directly impacts the production efficiency and product quality of microbial fermentation. As a practitioner in the industrial fermentation sector, are you searching for a high-quality fermentation raw material that can enhance production efficiency, reduce costs, and improve product quality? Corn Steep Liquor (CSL) powder is your optimal choice.

Corn Steep Liquor Powder: A New Choice for Organic Agricultural Fertilizers

Selecting an efficient and eco-friendly organic fertilizer is crucial for enhancing soil quality and promoting crop growth. Corn Steep Liquor (CSL) powder emerges as a novel option in the realm of organic agricultural fertilizers.

What are the benefits of applying amino acid powder(NPK 14-0-0) to plants?

Amino acid powder can provide organic nitrogen, and plants can directly absorb and utilize the amino acids in the amino acid powder through roots or leaves, making it easier to produce protein and saving the energy required to produce amino acids.

Corn steep liquor powder: Cost-effective Feed Additive

Corn steep liquor powder can be used as a feed protein source or as food for beneficial microorganisms in feed fermentation (fermentation medium), promoting the growth of beneficial microorganisms, thereby improving the nutritional utilization of feed, reducing feed costs, and improving animal growth performance; it is widely used in feed additives for ruminants, chickens, aquatic feed, etc.

Corn Steep Liquor Powder: High-quality fermented feed ingredients

the use of feed produced by adding CSL powder fermentation can reduce and improve feed digestibility, reduce morbidity, increase daily weight gain, improve feed digestibility, and reduce feed-to-meat ratio, which has extremely high economic value.

Corn steep liquor powder: high-quality nutritional supplement for ruminants

corn steep solids and molasses can safely replace the concentrated feed in the diet, providing cows with abundant energy and protein; And it will not affect the feed intake of cattle. CSL powder contain 43% crude protein, 35% amino acids, 7% organic nitrogen, 21% lactic acid, and 31% carbohydrates. It is commonly used in the feed industry as a protein source for cattle, sheep and other animals.